Poultry has little bone volume and rarely requires crushing. The raw material usually has high moisture content and less fat when compared to beef. Kontinuer has developed four systems to process this material in order to transform it into a high value-added product. The material can be treated by a cooking system performed by discontinuous or continuous loads. It is also possible to use a mixed system with the Slurry system, with low steam consumption.

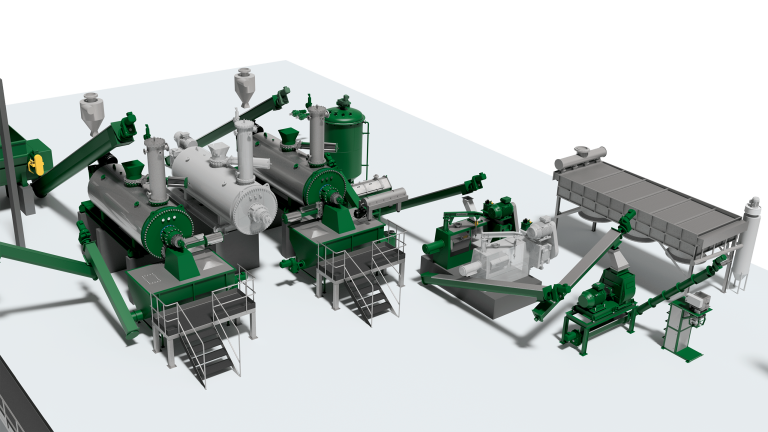

Batch System

Cooking is done by discontinuous loads in a Batch Digester, with temperatures ranging from 115°C to 135°C, depending on the raw material. It is the most widely used process in small productions, or when it is necessary to separate the raw material to obtain different final product qualities.

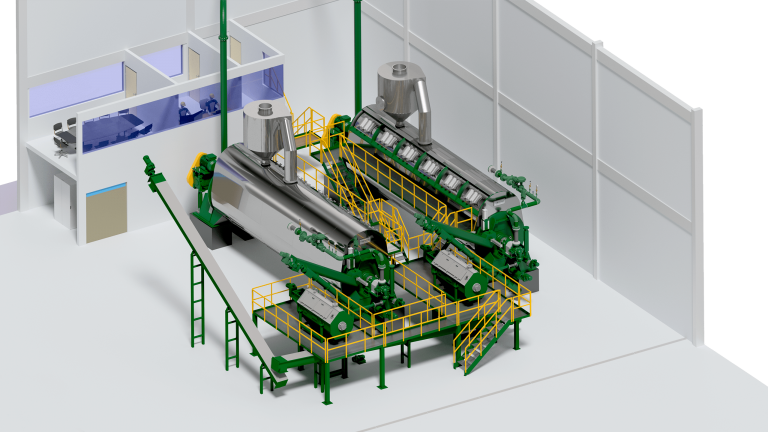

Continuous System

This cooking system is performed continuously, with controlled inlet and outlet temperatures. Depending on the type of raw material, the Continuous Digester of the Equacooker (tubular axis) or Disc type is used. It is the ideal process for large productions, with a single final product, good palatability, and optimized steam consumption.

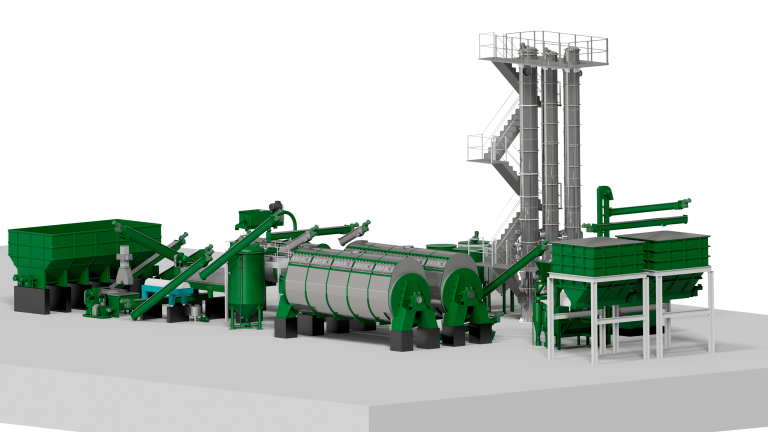

Low Temperature System

Prior coagulation of proteins separates the solid from the liquid and, subsequently, vacuum evaporators and disc dryers are used to remove moisture. It is the system recommended for large productions where the raw material contains a high moisture content. The final quality of the product is improved and the amount of steam required for the process is reduced.

Dual Channel System

It is a combination of the Continuous System with the Low Temperature System. The protein is coagulated and, subsequently, the product is processed as in the Continuous System. It is possible to obtain a final product with the quality of the Continuous System, but with less steam consumption. It is also recommended when it is necessary to increase production in an already existing line.

Slurry System

In this system, the raw material is cooked at a low temperature in a vacuum evaporator that uses boiler steam as a source of energy. Afterwards, the fat is separated in a decanter and the material is pressed. The process is recommended when the objective is low steam consumption and a high-quality final product.