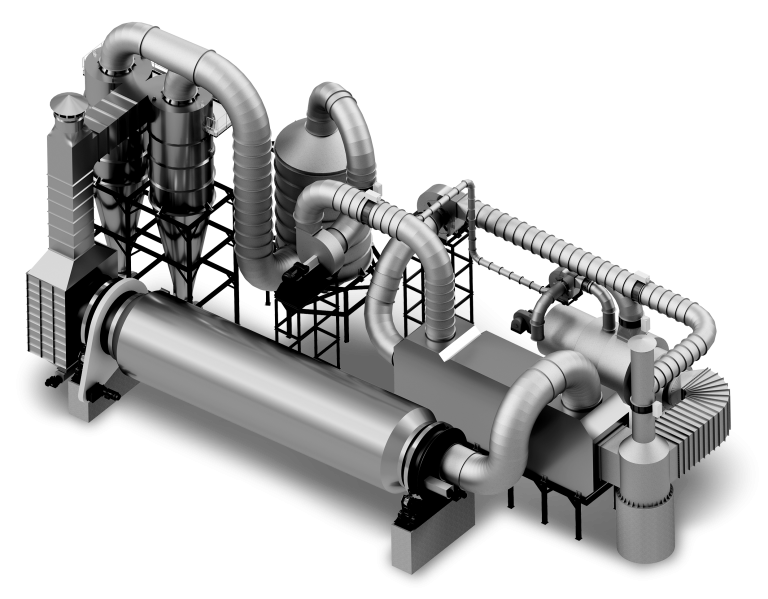

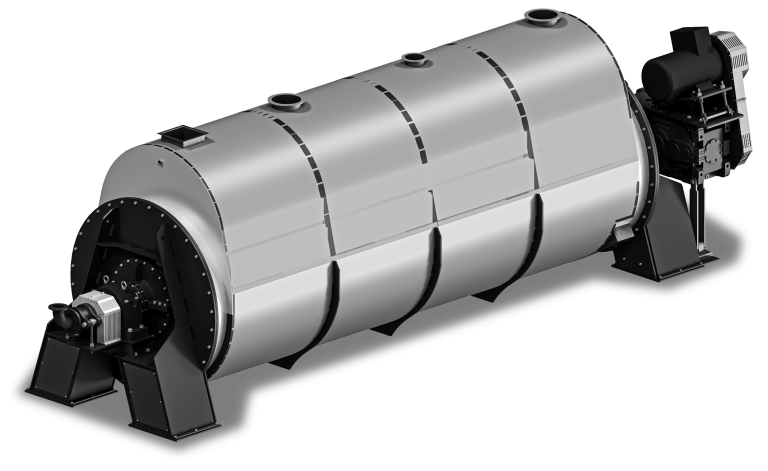

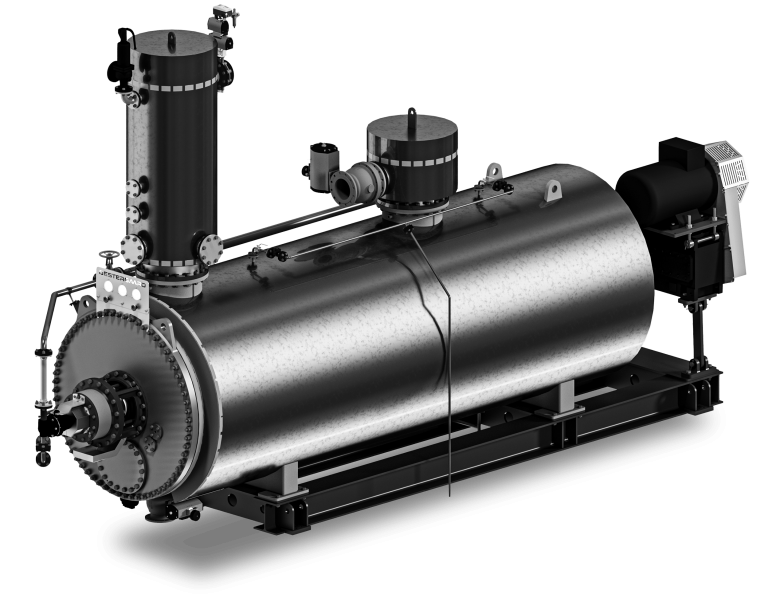

For drying, pressurized indirect steam or hot air directly on the raw material is used to separate the water by evaporation. The process is used to dry meal (from beef, fish, feather, hair, and blood), vegetable meal, and slurry. The dryers using indirect steam have the advantage of treating odors resulting from the steam and they ensure greater energy efficiency. We usually work at a temperature between 90°C and 110°C at the product’s outlet. Whereas in the direct hot air system, temperatures are variable, depending on project specifications. The advantage is a higher final product quality.

The raw material is free of fat and to choose the type of hot air dryer, it is important to know the type of fuel to be used: natural gas, LPG, BPF or furnace for burning wood. It is also possible to develop solutions that combine several types of dryers, according to the moisture, efficiency and quality required.