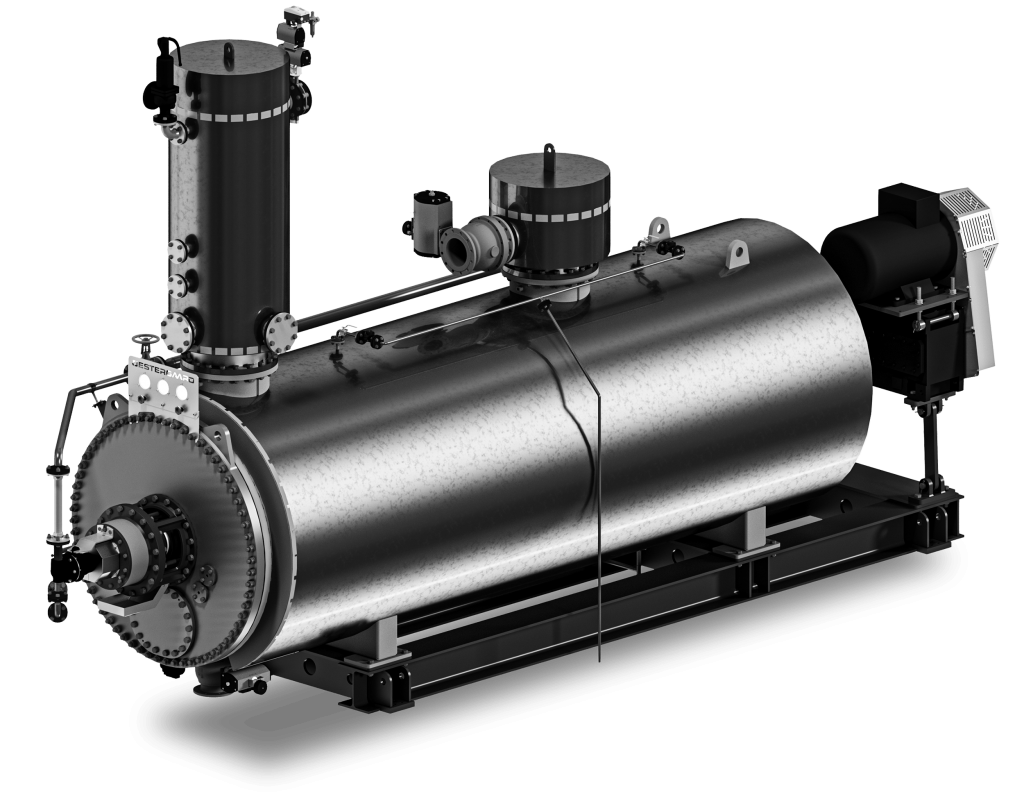

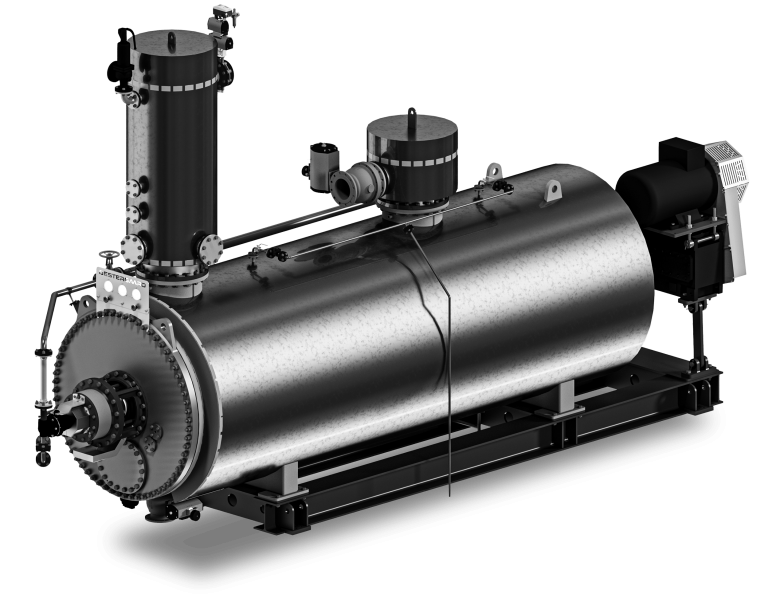

The Kontinuer Batch Cooker are used for cooking, hydrolysis, sterilization, and drying of any raw material of animal origin. The method consists in the heat exchange that takes place from the contact between the product and the heated surfaces inside the equipment. An efficient purge system eliminates the condensate inside the shaft, ensuring maximum equipment efficiency. The Batch Cooker may be manufactured in models with and without pressure inside the body, fulfilling the most stringent international standards.

Kontinuer Advantages

-

Processed material homogeneity;

-

High yield and low energy consumption;

-

Rigid, resistant, and easily accessible for maintenance structure;

-

Fully automated production process;

-

Comply with the requirements of the NR-12 standard.

Equipment flow

Crushed raw material of animal origin of any kind, including feathers.

Cooked or dry homogeneous material.

Technical specifications

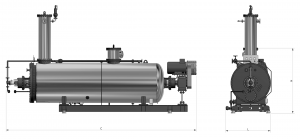

| MODEL | VOLUME (m³) | POWER (kW) | WEIGHT (ton) | OVERALL DIMENSIONS (mm) | ||

|---|---|---|---|---|---|---|

| L | W | H | ||||

| BCP-50 | 5,00 | 37 | 12,5 | 5200 | 1990 | 2650 |

| BCP-65 | 6,50 | 45 - 55 | 13 | 6800 | 1900 | 2800 |

| BCP-85 | 8,50 | 55 | 18,7 | 7600 | 2000 | 3000 |

| BCP-100 | 10,00 | 75 | 22,3 | 8530 | 2000 | 3000 |

| BCP-130 | 13,00 | 90 | 27,5 | 9500 | 2000 | 3000 |

| BCP-160 | 16,00 | 110 | 35 | 9500 | 2150 | 3400 |