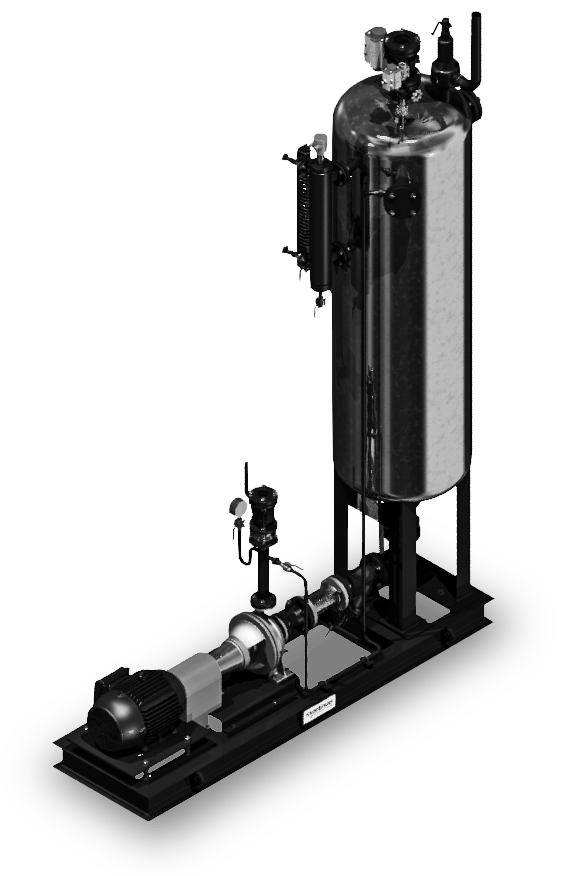

Heat energy is the greatest operating cost at a processes plant for bovine or fish co-products. Kontinuer has developed different solutions to reduce energy costs in this type of plant. The most used solution is the Automatic Condensate Recovery System (ACRS), which sends high-pressure and high-temperature condensates directly to the steam generating boiler. This prevents loss of energy of the material due to depressurization and revaporizing, with the consequent loss of temperature. With this system, there are heat energy savings ranging from 12% to 15%. With the heat exchanger of the hull tube type, it is possible to reuse the phase exchange energy by condensation. The idea is to reuse this energy in the form of hot water for other cleaning needs or for other processes in the plant or in the slaughterhouse. Whereas the Evaporator reduces between 30% and 35% the heat energy needs in a low temperature plant.