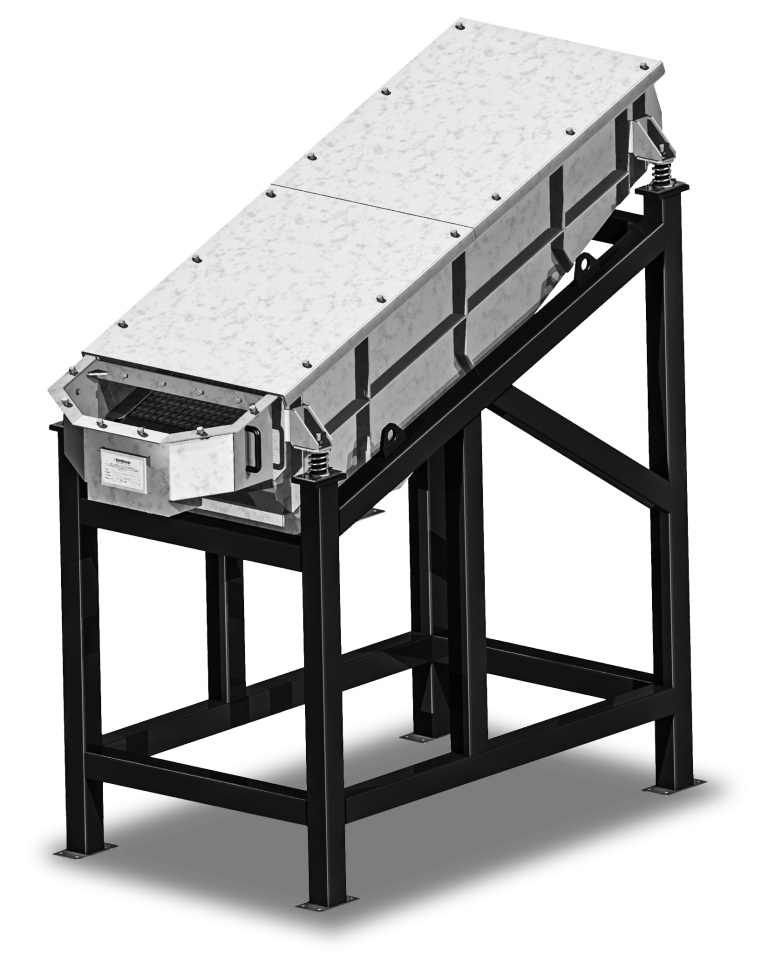

The grinding process ensures a maximum particle size for meals. Particle size is required in different markets to provide a good mixture with other products as well as to prevent animals from chocking. Meal temperature, fat percentage, bone content or mineral matter, and mesh opening are some of the variables that determine the mill’s production. The peripherals are also important, such as controlled feeding hopper, buffer hopper at the exit, and particle separation by grinding. It is possible to install a vibrating sieve to separate in advance those particles that are in accordance with the expected particle size. The most common mill type is the high-rotation hammer mill featuring high durability and reduced maintenance. Impact and shearing mills are also used, depending on the type of raw material and final product specifications.