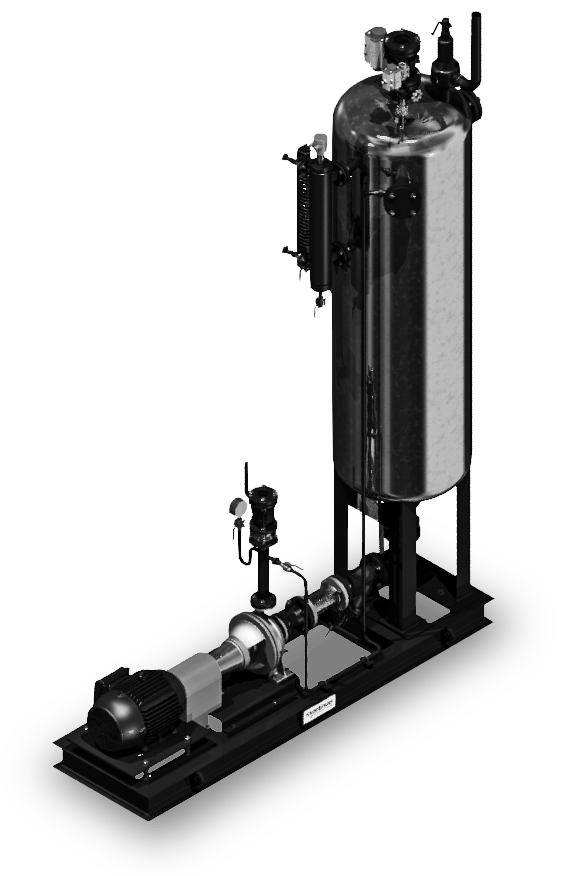

The Kontinuer Condensate Recovery System (CRS) ensures steam savings in meal plants, reducing costs between 10% and 15%. In a normal process, without the CRS, the condensate generated in the cooking process returns to the boiler’s feeding tank, with loss of pressure and temperature. With the CRS, the condensate removed from the digester and dryer shaft is stored in a tank at constant temperature and pressure. The boiler will consume a lesser amount of fuel to transform the condensate into saturated steam again, thus reducing the waste of energy and fuel.

Kontinuer Advantages

-

Improves boiler efficiency;

-

Savings of 10% to 15% in boiler fuel costs;

-

Reduces the loss of pressure and temperature in the boiler’s feeding tank;

-

Fully automated system;

-

Comply with the requirements of the NR-12 standard.

Equipment flow

Condensate generated in the cooking process, from the digester and dryer shaft.

Steam for the boiler.

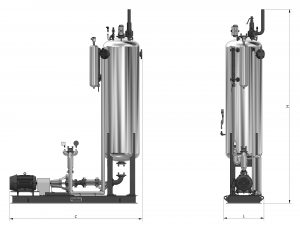

Technical specifications

| MODEL | POWER (kW) | WEIGHT (ton) | OVERALL DIMENSIONS (mm) | ||

|---|---|---|---|---|---|

| L | W | H | |||

| SRC-12 | 18,5 | 1,7 | 2460 | 800 | 3700 |

| SRC-16 | 22,00 | 2,0 | 2460 | 800 | 3700 |