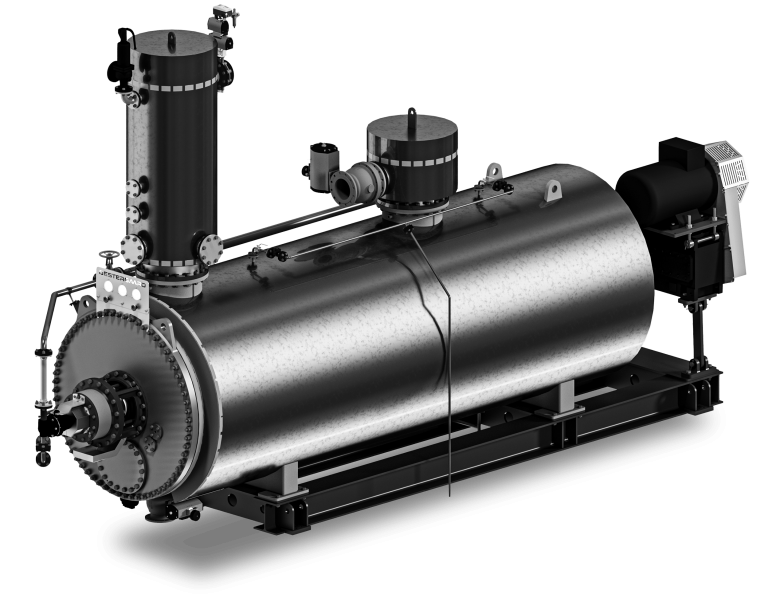

Sterilization eliminates possible germs contained in the product, including in the sporulated form, which ensures the fulfillment of standards required in some countries. Products can be sterilized at the exit of cooking, and fats and meals prior to grinding. The process consists in raising the product’s temperature to 133°C at 3 bars of pressure during 20 minutes. It is a system that must be completely automated, with production control, and pressure, temperature, and time logs, which can be presented in the form of graphs. Automation is necessary to ensure the quality of the final product. The Meal Sterilizer injects steam directly into the product to raise the temperature and pressure, and a cooler prevents condensation. Whereas the cooked material sterilizer treats the product before pressing and it also works with direct steam without the need for a cooler. The fat sterilizer may be required to adjust some products in regard to legislation.